Digital providers firm Ricoh has partnered with industrial manufacturing agency Siemens to optimize aluminum binder jetting (BJT) expertise for industrial-scale mass manufacturing.

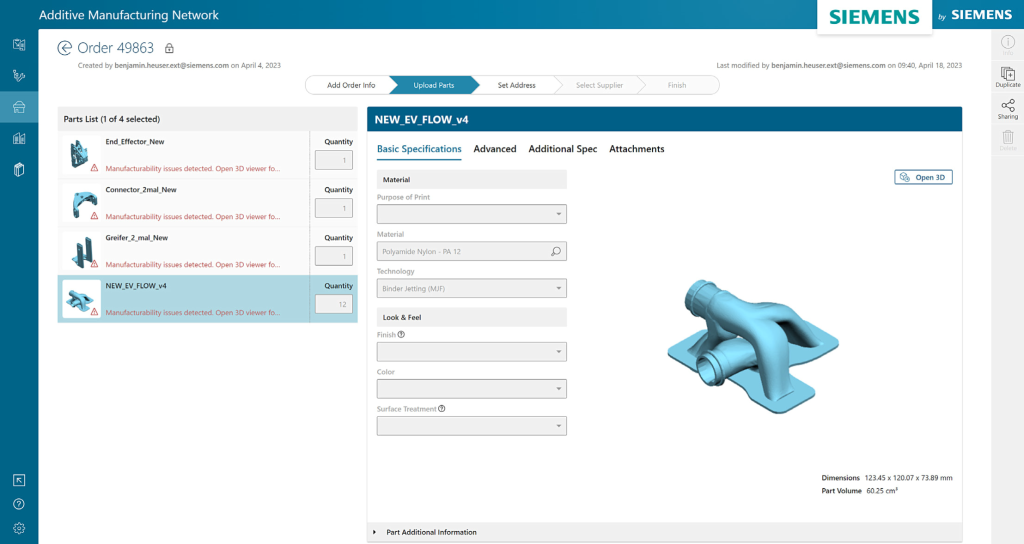

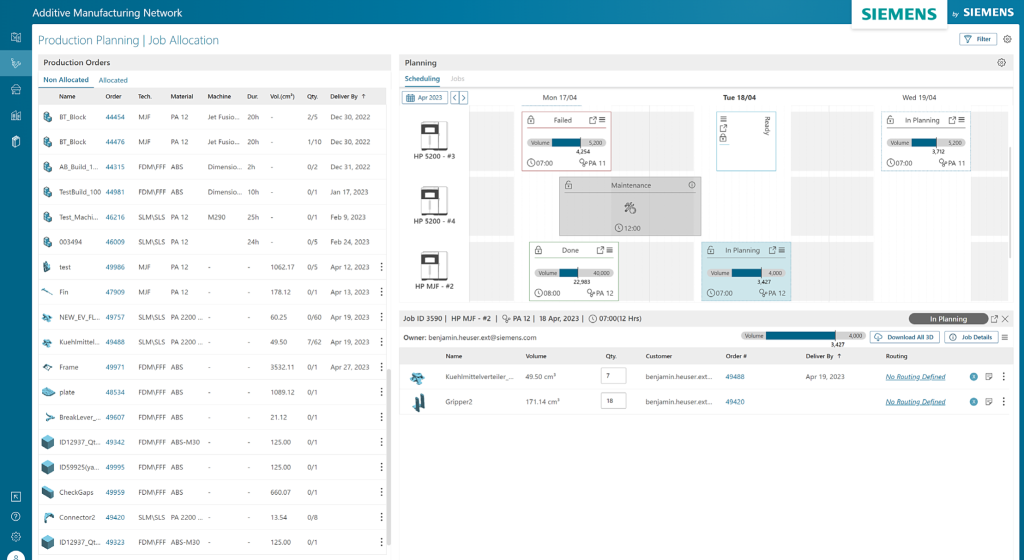

Ricoh is using Siemens’ Additive Manufacturing Community digital platform to extend the effectivity of its BJT course of, scaling the expertise to fulfill industrial manufacturing calls for.

Ricoh goals to construct a digital platform that optimizes the inner processes and manufacturing of its aluminum binder jetting expertise. It will span from 3D print job preparation to the supply of completed parts. The corporate hopes to “digitally rework” its course of service providing to fulfill a rising vary of business additive manufacturing clients, particularly throughout the electrical car (EV) trade.

Ricoh has additionally built-in Siemens’ Brownfield Connectivity, and is actively amassing and storing info on the processes vital for manufacturing management and high quality stabilization.

“The manufacturing of aluminum elements is a holy grail for the additive trade and we’re delighted that Ricoh has chosen Siemens’ Additive Manufacturing Community capabilities from the Siemens Xcelerator portfolio of trade software program to assist them commercialize a a lot sought-after course of,” commented Zvi Feuer, Senior Vice President, Digital Manufacturing Software program, Siemens Digital Industries Software program. “Our collaboration with Ricoh will apply its experience in additive manufacturing with our information and expertise in delivering additive-specific operations administration expertise throughout a large spectrum of industries – from order seize, manufacturing planning, and manufacturing to half supply transaction closure”

“Collectively, Siemens and Ricoh are working to ship repeatability and consistency on the scale wanted to actually benefit from utilizing strong and repeatable aluminum additively manufactured elements within the business world,” added Feuer

Each Ricoh and Siemens are hoping for an early commercialization of this new binder jet providing.

Scaling Ricoh’s binder jetting expertise

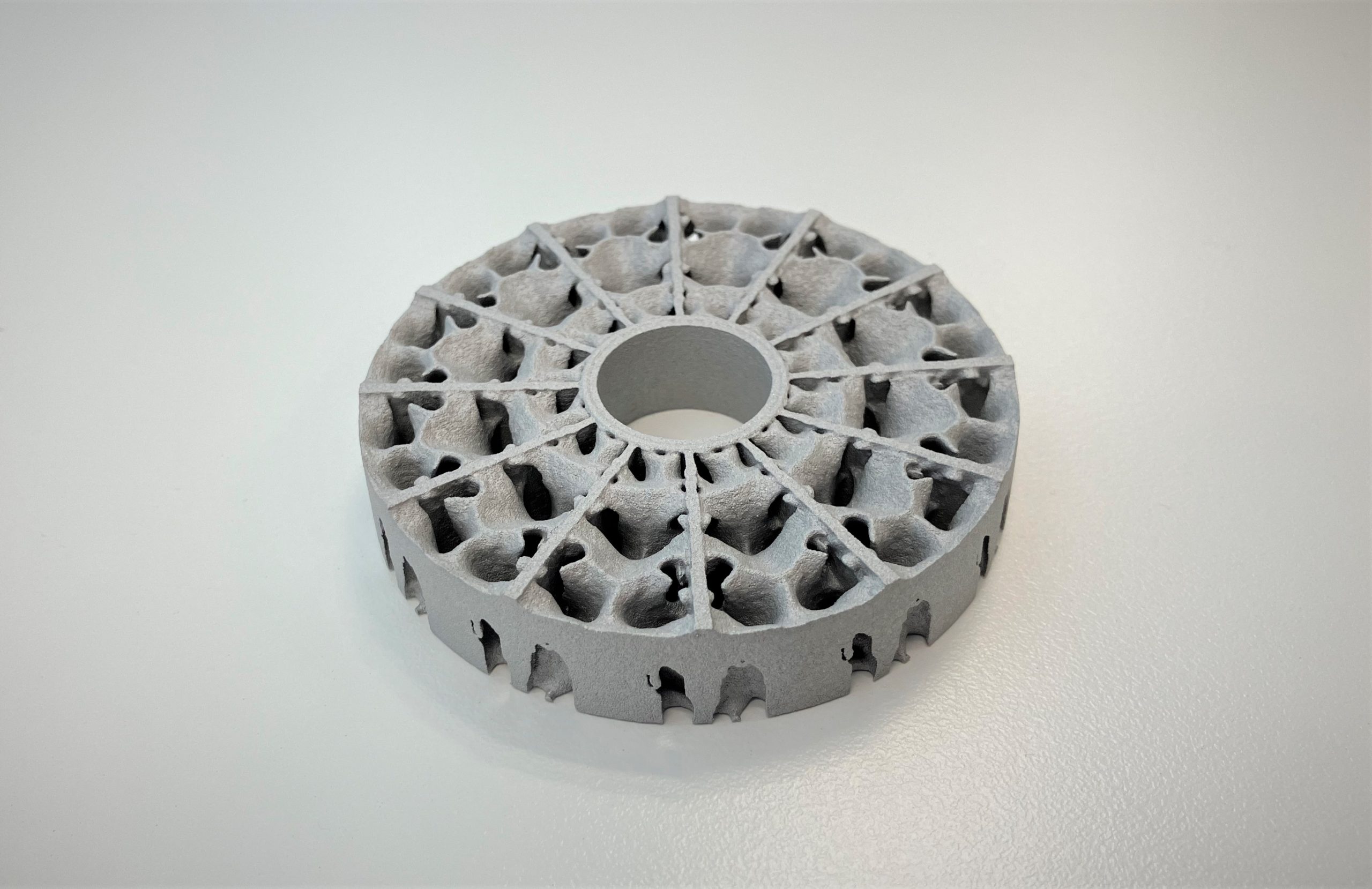

Ricoh’s proprietary binder jetting expertise leverages the corporate’s inkjet printing experience to fabricate steel elements with complicated geometries that will not be potential by means of standard manufacturing strategies.

Through the BJT course of, aluminum-alloy powder is dispersed over the construct space. This powder is then solidified right into a predetermined form by a specifically formulated binder. This course of is repeated layer-by-layer, till the ultimate half has been produced. The finished “inexperienced half” is then sintered in a furnace, making a dense end-use part.

In line with Ricoh, the corporate’s binder jetting expertise provides a number of benefits for the manufacturing of aluminum elements. Notably, this course of is alleged to allow weight reductions and improved warmth alternate efficiency, by facilitating the manufacturing of shapes not potential with standard processing applied sciences. Binder jetting additionally reportedly provides vital time and materials financial savings, due to its excessive productiveness and skill to recycle materials.

By way of this new partnership with Siemens, Ricoh hopes to additional its aim of realizing “a zero-carbon society.” The Japan-based firm goals to attain zero GHG emissions all through the complete worth chain, permitting the mass-production of extremely energy-efficient merchandise utilizing its steel 3D printers.

“Ricoh will allow our clients to fabricate modern aluminum parts which have by no means been produced earlier than by any course of and can work with them to understand new buyer worth within the space of electrification of EVs and different types of mobility,” defined Tokutaro Fukushima, Normal Supervisor of Ricoh’s Additive Manufacturing Enterprise Middle.

“By combining Siemens’ highly effective options and information with Ricoh’s aluminum BJT, we can present our clients with extremely dependable and sensible programs for mass manufacturing purposes. We hope to advertise electrification along with our clients and contribute to fixing social points similar to realizing a zero-carbon society.”

3D printing for mass manufacturing

Scaling additive manufacturing to fulfill demand in industrial mass manufacturing is a distinguished development throughout the present 3D printing trade.

Earlier this 12 months, Utah-based 3D printed elements producer Merit3D introduced that it had agreed to ship ‘the most important ever 3D printer elements order.’ Florida-based adhesives producer Adhesive Know-how Company positioned the order of over 1 million 3D printed elements again in Might.

The parts in query are hangers for epoxy merchandise and are being delivered at a charge of 40,000 items per week. This cope with Adhesive Know-how Company kinds a part of Merit3D’s mission to re-shore mass manufacturing into the US

Elsewhere, Austrian engineering agency and OEM Incus GmbH not too long ago introduced the launch of its latest Lithography-based Metallic Manufacturing (LMM) 3D printer, the Hammer Pro40. This new steel 3D printer has been designed to fulfill calls for in mass manufacturing, provides upgraded manufacturing capabilities, and may be deployed immediately on the manufacturing facility ground.

The brand new Incus Hammer Pro40 will likely be offered for the primary time at Formnext 2023 in Frankfurt, between November 7-10.

Subscribe to the 3D Printing Business e-newsletter to maintain updated with the most recent 3D printing information. You can too observe us on Twitter, like our Fb web page, and subscribe to the 3D Printing Business Youtube channel to entry extra unique content material.

Are you curious about working within the additive manufacturing trade? Go to 3D Printing Jobs to view a choice of obtainable roles and kickstart your profession.

Featured picture exhibits a high-efficiency air-cooling heatsink created by RICOH’s aluminum Binder Jet Know-how (BJT) system. Photograph through Ricoh.