Conformal coating inspection is now more difficult because the digital development within the high-tech industries considerably elevated the complexity of Printed Circuit Board design with extra joints, larger part densities, and new bundle applied sciences on the Printed Circuit Board assemblies (PCBAs).

A conformal coating is a skinny polymeric movie utilized to the floor of a printed circuit board (PCB) to guard the board and its parts from the setting and corrosion. Conformal coating is important for the board manufacturing course of as a result of it ensures digital units’ reliability and longevity by defending them from environmental elements akin to moisture, mud, and corrosive substances. The safety offered by conformal coatings permits for larger voltage gradients and nearer monitor spacing, in flip enabling designers to satisfy the calls for of miniaturization and reliability.

Moreover, the conformal coating may also support the producer in guaranteeing compliance with the IPC requirements, particularly for these required to stick to the requirements of IPC Courses 2 (PCBAs with good high quality and sturdiness) and three (industries with essentially the most stringent product necessities, akin to aerospace and medical). Because of the demanding nature of the business, electronics failures are insupportable because the merchandise are required to cater to excessive, steady and significant efficiency beneath harsh environments.

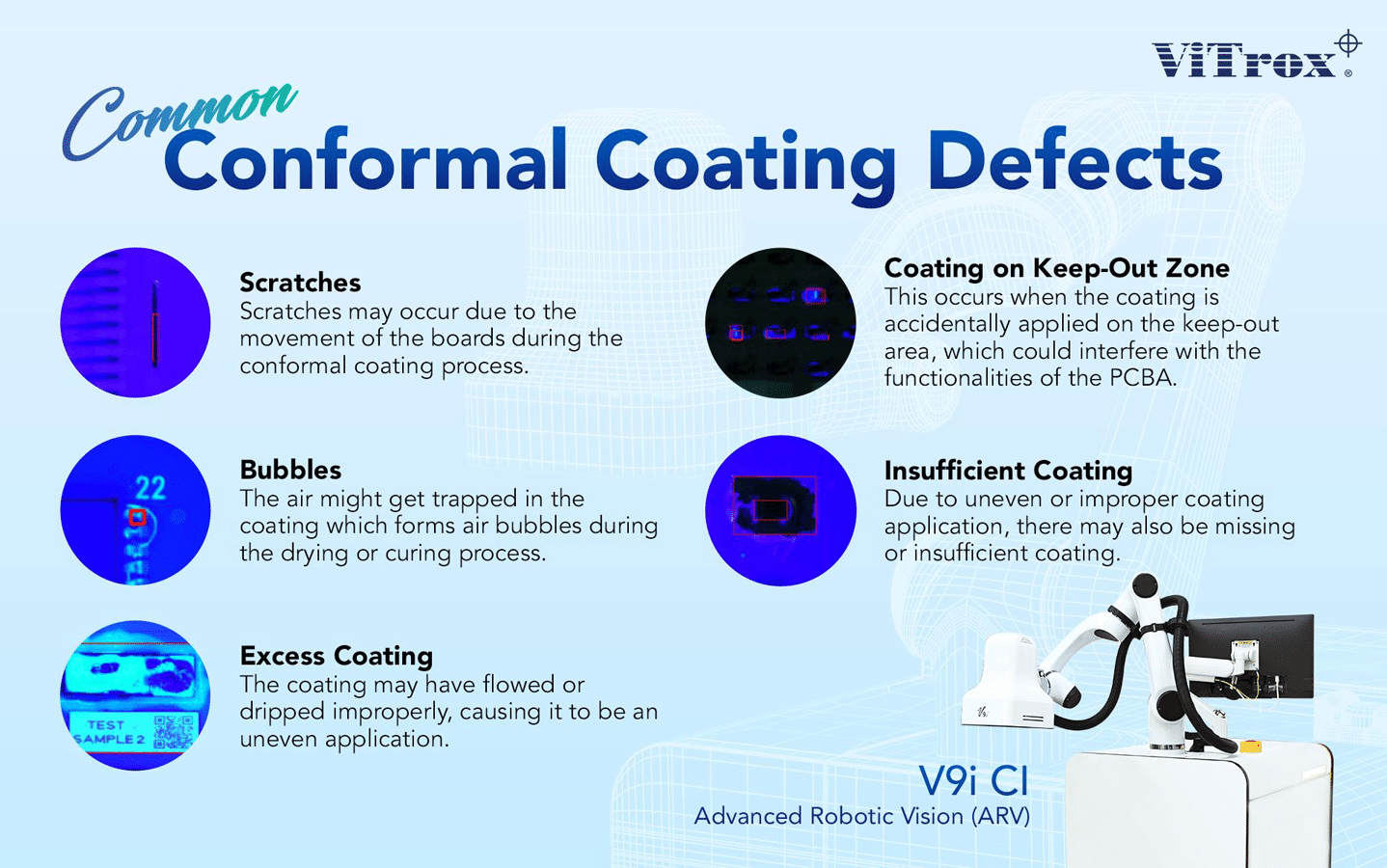

A newly manufactured board will usually operate nicely. Nevertheless, its efficiency can rapidly deteriorate because of corrosion, mould progress, leakage, thermal shock and electrical failures. Due to this fact, it is very important have the coating utilized accurately and evenly on the PCB in compliance with the IPC Customary (IPC-A-610). Defects on the PCB which can be generally discovered in the course of the conformal coating course of embody bubbles, lacking/inadequate coating, coating on Preserve-Out Zone, overseas objects on coating, and plenty of extra.

Challenges Posed by Handbook Inspection & Standard CC AOI Inspection

Within the present market, conformal coating inspection is commonly performed by both guide labour or utilizing standard CC AOI. These two strategies pose challenges to the standard and general productiveness of inspection.

Handbook inspection or standard CC AOI inspection shouldn’t be ultimate for customers as it’s much less efficient and has decrease accuracy and decrease velocity. Human misjudgement could occur and it results in high quality points. In addition to that, guide inspection lacks traceability which causes customers to not have correct references for complete inspection evaluation and preventive motion. For the standard Conformal Coating AOI, it doesn’t have the pliability to regulate the digicam angle which ends up in a restricted inspection angle.

V9i Superior Robotic Imaginative and prescient (ARV) Answer: Assembly Your Conformal Coating Inspection Wants

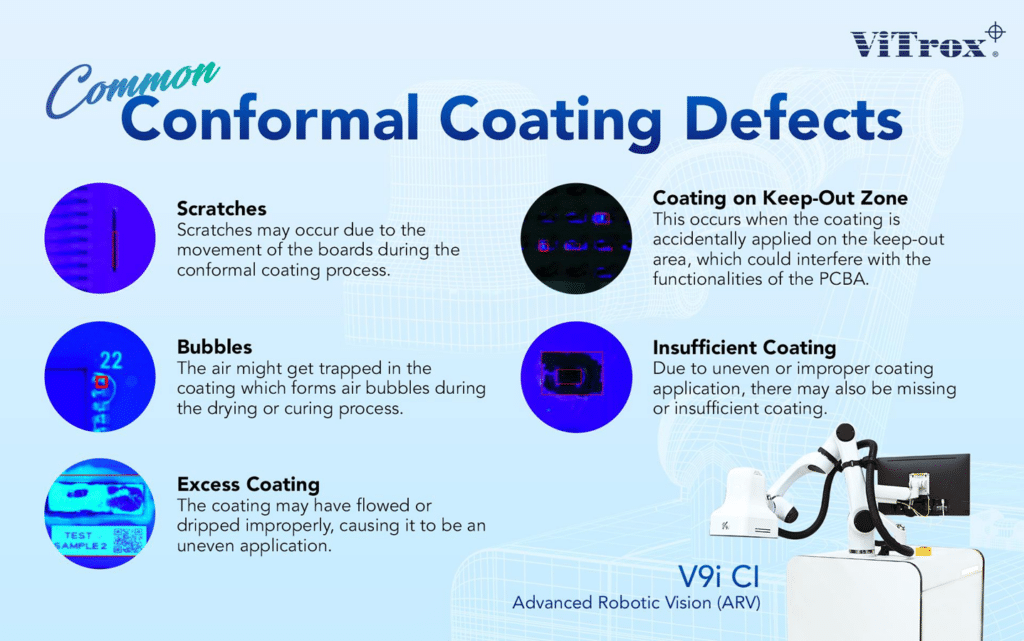

As compassionate innovators, ViTrox understands the importance of getting a highly-accurate and dependable inspection system. It aids producers in detecting any defects or non-conformities within the coating and minimises escapee in the course of the manufacturing course of. Therefore, we innovated the award-winning V9i ARV Answer – and listed here are a few of our key options which shall be a game-changer to extend inspection accuracy, consistency and velocity:

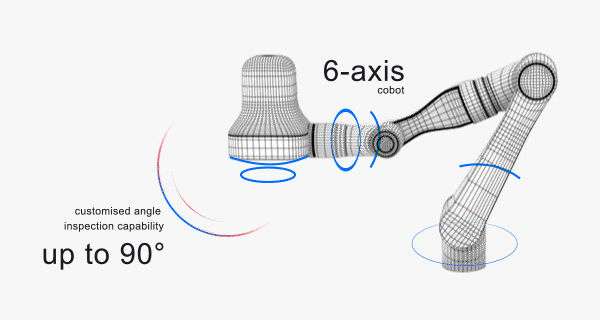

- 6-Axis Collaborative Robotic (COBOT)

The V9i ARV resolution is a 6-axis COBOT-based automated conformal coating inspection system that permits versatile inspection capabilities. The digicam angle could be adjusted as much as 90°, enabling conformal coating full protection examination. By the usage of automation, the inspection course of is made extra impactful and efficient, guaranteeing accuracy and consistency. The target is to permit customers to carry out coating inspection with excessive flexibility as a human hand however with higher consistency.

- Configurable Imaginative and prescient Module Design

Many of the conformal coating consists of ultraviolet (UV) fluorescence for the person to carry out the inspection. V9i ARV system consists of an ultraviolet-white (UVW) module specialising in conformal coating inspection. The UV lighting is innocent to the human eye with a 365nm wavelength which permits the person to function it safely. One other essential function of the V9i ARV system is conformal coating thickness measurement. V9i ARV system gives coating thickness measurement capabilities for a coating vary inside 25μm ~ 500μm, with accuracy and repeatability decrease than 5μm. Our V9i ARV resolution is constructed with multi-focal imaginative and prescient, permitting inspection starting from 5mm to 200mm, thus leading to high-resolution photos as clear as 14um/px for small defect inspection. The V9i ARV resolution ensures full inspection protection and all the time delivers dependable and constant outcomes.

- Compact, Moveable and Ergonomic Machine Design

Not like standard CC AOIs, our V9i ARV resolution is compact and transportable and may simply be docked subsequent to conveyors with out growing the size of the manufacturing line, leading to a extra versatile and environment friendly inspection course of. Customers can join the V9i ARV resolution to their manufacturing for inline manufacturing mode by utilizing the SMEMA connection for upstream and downstream communication. In any other case, customers can place the system for offline mode dialogue with the present conveyor.

- Person-friendly Setup for Zero-Expertise Personnel

V9i ARV is user-friendly, and other people with out programming expertise can simply undertake it inside a brief time frame. Growing a program from scratch would take roughly 2-3 hours, relying on the person’s expertise with the system. The system can save up loads of time in growing a program by means of Superior CADless programming by studying the golden board samples. Therefore, customers solely have to concentrate on fine-tuning or extra measurements required.

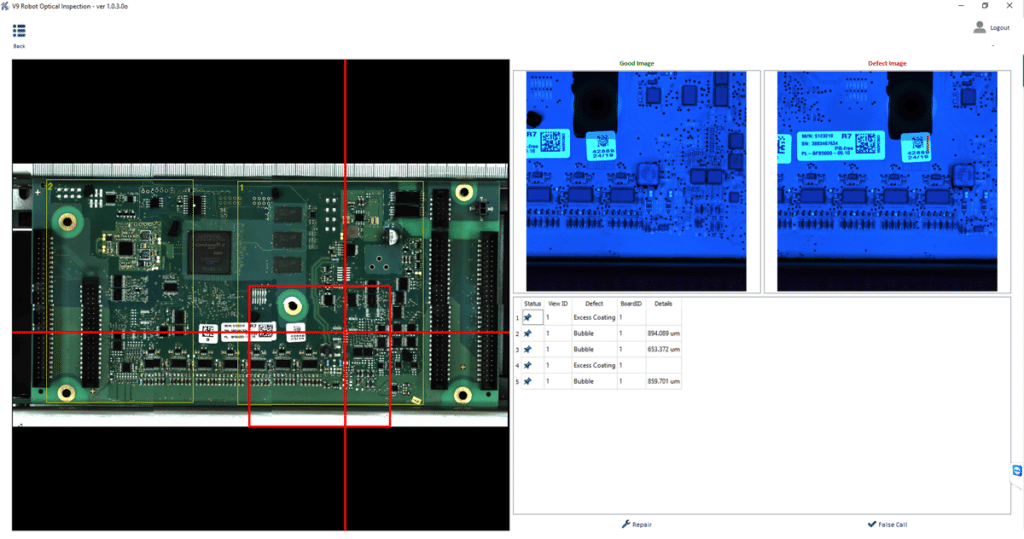

The intuitive graphic person interface (GUI) additionally creates a recent person expertise that makes it easy to write down programmes with minimal effort. This GUI allows customers to manage the imaginative and prescient motion for viewing, utilising only one click on to kickstart inspections and studying processes, in addition to to view the inspection outcomes updates concurrently on the identical interface. Additionally it is easy to examine all boards utilizing a single board setting.

The mixture of {hardware} and software program has introduced outstanding inspection outcomes and high quality assurance to our prospects. After the inspections, all information will stream to the automated restore station (VVTS) for the operator to purchase off at a distant station or the system space. For all prospects, particularly automotive prospects, inspection information is essential and each board inspected in V9i ARV shall be recorded and saved in a database ViTrox Database Statistical Course of Management (VDSPC) 2.0 for future evaluate. Customers can simply hint again the inspection information based mostly on barcode scanning. At the side of the period of Sensible Manufacturing, V9i Gen 2.0 is able to join with Trade 4.0 Manufacturing Intelligence – V-ONE by means of ViTrox and SMEMA connectivity.

- Intensive Inspection Capabilities

Along with being a system for inspecting conformal coatings, ViTrox’s V9i ARV resolution additionally serves as a remaining inspection resolution. On high of conformal coating inspections, customers may also use the V9i ARV resolution to carry out remaining meeting inspections! It’s a cost-effective funding as a result of the customers can accomplish two inspection processes with one resolution. The V9i ARV resolution may also be configured to boost inspection protection and effectivity, offering much more worth to your inspection course of.

One of many configuration choices is the V95i ARV Answer Rotator, which helps multi-angled PCBA and Field Construct inspections inside an answer, whereas the V97i ARV Answer Flipping Conveyor helps V9i ARV to carry out high and backside inspections. This configuration permits customers to carry out fast inspections with out setting one other flipper within the line, so keep tuned for extra thrilling updates on this configuration!

Key Takeaway

To summarise all of it, conformal coating inspection is a vital step to make sure compliance with business requirements and to delay the lifespan and value of your PCBAs. V9i ARV can assist customers handle the potential points arising from guide conformal coating inspections. Most significantly, it’s an Trade 4.0-ready resolution with real-time monitoring, evaluation and preventive actions that assure inspection accuracy, consistency, traceability and reliability!