Following its partnership with Castor, Oqton has launched Oqton Construct High quality software program, enhancing Manufacturing OS (MOS) and 3DXpert merchandise, to hint half high quality and consider construct efficiency.

Oqton Construct High quality combines 3DXpert Construct Simulation, MOS Construct Monitoring, and 3DXpert Construct Inspection to supervise the entire manufacturing course of and rectify errors in construct setup, printing, and supplies. Figuring out and rectifying anomalies at an early stage ensures profitable builds, from preliminary inspection to the ultimate half. This allows producers to determine constant processes for each prototyping and manufacturing, leading to cost-effective, high-quality elements. Oqton is showcasing the capabilities of Construct High quality in its Corridor 11.1, sales space C22 at Formnext 2023.

“Lately, metallic additive manufacturing has developed as a expertise for dependable serial manufacturing of end-use elements,” mentioned Tomasso Tamarozzi, Product Director, Additive Manufacturing, Inspection & Simulation, Oqton. “Nevertheless, the trade nonetheless needed to take very deliberate measures to make sure that manufacturing high quality was held to very excessive requirements. There was a scarcity of standardized procedures, disparate {hardware} parts, and a number of software program distributors, however not one dependable resolution. With the introduction of Construct High quality, Oqton is delivering a single actionable, dependable resolution that addresses all these facets. By way of collaboration with strategic companions, resembling Baker Hughes and our colleagues in 3D Techniques, Oqton can present a dependable printer-agnostic resolution constructed on AI and physics-based simulation. I sit up for the chance to proceed to broaden our portfolio with options resembling this that ship distinctive, important advantages for producers.”

In different information, Pennsylvania-based service bureau FreeFORM Applied sciences has chosen Oqton’s software program, Manufacturing OS, and 3DXpert to boost its manufacturing workflow.

AI-powered high quality assurance for additive manufacturing

Oqton Construct High quality serves producers utilizing additive manufacturing applied sciences, together with OEMs, service bureaus, engineering groups, and high quality assurance professionals. The answer concentrates on important phases earlier than, throughout, and after the construct to optimize processes and outcomes.

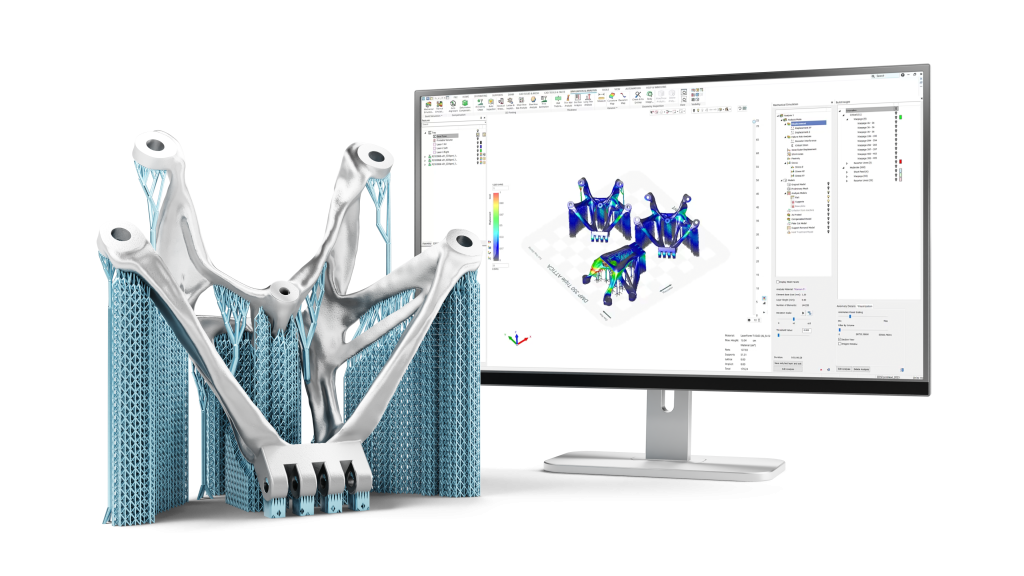

Previous to half manufacturing, the intention is to foretell print high quality and get rid of design points earlier than initiating the primary print. Throughout this part, 3DXpert Construct Simulation performs an important position in predicting printability issues and stopping half overheating. It achieves this by suggesting minor design revisions and offering suggestions for half orientation and help methods as a part of the construct preparation course of.

The software program employs parallelization and voxel expertise to streamline simulation, minimizing iteration time and materials wastage. This ensures top-quality outcomes on the primary try. Throughout the construct, MOS Construct Monitoring, created in partnership with Baker Hughes, makes use of AI fashions to detect potential defects in real-time, permitting customers to trace every half’s each layer. This performance boosts course of reliability, maintains high quality, and prevents monetary losses from half failures.

After the construct, the standard inspection course of ensures that the elements meet design specs. 3DXpert Construct Inspection helps customers analyze the ultimate elements in comparison with the preliminary expectations. Any anomalies set off corrective actions to boost future half high quality and maximize manufacturing output.

FreeFORM Applied sciences boosts manufacturing effectivity with Oqton’s Manufacturing OS

FreeFORM Applied sciences produces 500,000+ elements yearly for various industries. By incorporating Oqton’s Manufacturing OS into its operations, the corporate will automate repetitive duties, enhance the estimating course of, and improve half traceability. The mixing of Oqton’s 3DXpert software program will streamline the whole additive manufacturing workflow. With Oqton’s help, this complete resolution goals to spice up manufacturing effectivity, positioning FreeFORM Applied sciences for sustained progress and competitiveness, notably in extremely regulated sectors.

Oqton’s software program is understood for its seamless integration with current workflows, breaking down information silos between enterprise methods like CRM, ERP, QMS, and PLM, says the corporate. The Manufacturing OS permits configurable manufacturing environments for real-time monitoring, enhancing course of visibility, historic record-keeping, and utilization enchancment via evaluation and optimization, benefiting producers searching for environment friendly and built-in options.

Oqton’s integration of 3DXpert with Manufacturing OS automates construct preparation, using AI to duplicate professional preferences and previous setups, encompassing duties like half orientation, help era, nesting, slicing, and construct course of simulation and compensation. This streamlined workflow from design to printing enhances manufacturing effectivity, saving time and assets.

“We awarded this contract to Oqton as a result of the staff has intensive experience in additive manufacturing processes, and Oqton’s Manufacturing OS platform was constructed from the bottom up particularly for AM,” mentioned Chris Aiello, VP of enterprise growth, FreeFORM Applied sciences. “This allows strong efficiency and ease of use even with essentially the most complicated workflows during which revision management is important. We’ll obtain considerably extra correct forecasts for the precise value of our manufacturing course of in comparison with estimated prices. Oqton discovered the steadiness between simplicity and complexity.”

Learn all of the 3D Printing Trade protection from Formnext 2023.

Voting has now began for the 3D Printing Trade Awards 2023. Forged your vote now!

What does the way forward for 3D printing for the following ten years maintain?

What engineering challenges will should be tackled within the additive manufacturing sector within the coming decade?

To remain updated with the newest 3D printing information, don’t neglect to subscribe to the 3D Printing Trade publication or observe us on Twitter, or like our web page on Fb.

Whilst you’re right here, why not subscribe to our Youtube channel? That includes dialogue, debriefs, video shorts, and webinar replays.

Are you in search of a job within the additive manufacturing trade? Go to 3D Printing Jobs for a number of roles within the trade.

Featured picture reveals 3D printed 3DS bracket being inspected on a monitor utilizing Oqton’s 3DXpert software program. Picture through Oqton.