Nikon SLM Options and Materialise are collaborating to prepared the following technology of Materialise construct processors for Nikon SLM Options printers for integration into the Materialise CO-AM platform.

The 2 corporations are extending their partnership in response to buyer requires enhanced half high quality, aggressive pricing and swift manufacturing. They consider by integrating the SLM construct processors into CO-AM they may equip producers with the proper machine and autonomy to customize their 3D printing processes.

As Nikon SLM Options has labored to develop greater machines with extra lasers, it’s processing much more information, and subsequently seeing elongated calculation occasions. Since this dangers impeding workflow effectivity, the corporate has recognized a must bridge the hole between information preparation and printing. Nikon SLM Options and Materialise have due to this fact amalgamated their experience to develop subsequent technology construct processors, which might be launched to customers of SLM’s NXG collection of machines and all SLM customers deploying Materialise software program options within the coming months.

The upcoming Materialise construct processor is alleged to expedite information processing and permits customers to customize their course of parameters to optimise software outcomes. Materialise has harnessed its BP Software program Improvement Package (SDK) to foster shut collaboration within the improvement of its next-gen construct processor, is alleged to have engineered a platform that can ‘markedly cut back’ the calaculation occasions for Nikon SLM customers. Machine parameters can even be capable to be optimised by the Nikon SLM Open Structure, whereas the Materialise BP SDK will enable customers to formulate parameters and create their very own IP. By fine-tuning print parameters, Materialise says usrs will be capable to improve value effectivity, manufacturing pace, and half high quality.

“Working with Materialise, we have now made a large leap in growing a high-performative construct processor,” commented Nicolas Lemaire, Product Supervisor – Software program, Product Management, and Strategic Partnerships at Nikon SLM Options. “With this subsequent technology of construct processors, our clients utilizing Materialise software program will save time throughout the print job setup and revenue from instruments to optimise their print course of.”

“Nikon SLM Options and Materialise share a imaginative and prescient of open programs that allow AM customers to make optimum use of their tools and join it to their most popular options,” added Bart Van der Schueren, CTO of Materialise. “We stay up for providing the subsequent technology of BPs to Nikon SLM Options customers and offering them entry to software program options protecting the entire AM workflow.”

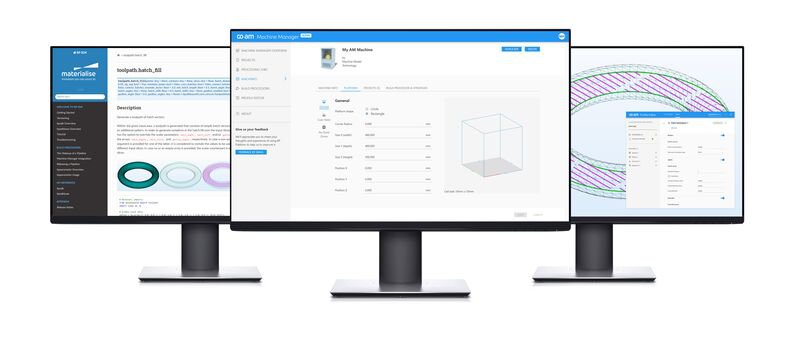

At the side of the brand new Materialise BPs, Nikon SLM Options customers will profit from direct machine connectivity to the Materialise CO-AM Software program Platform through SLM.Hyperlink, an open platform communication interface. CO-AM has been designed to permit customers to combine 3D printers into present manufacturing programs, refining the additive manufacturing workflow from order to supply.

Already this week, Materialise has introduced integrations with HP’s Multi Jet Fusion and Steel Jet Fusion applied sciences. The corporate additionally introduced updates to its CO-AM High quality & Course of Management (QPC) system. In the meantime, SLM Options has notably rebranded to Nikon SLM Options.