On this interview, Olivier Diegerick, the EMEA Additive Manufacturing Software program Portfolio Improvement Govt at Siemens Digital Industries Software program, make clear the agency’s built-in method in the direction of additive manufacturing (AM) by way of its software program options.

Learn extra within the 3D Printing Business Govt Interview collection.

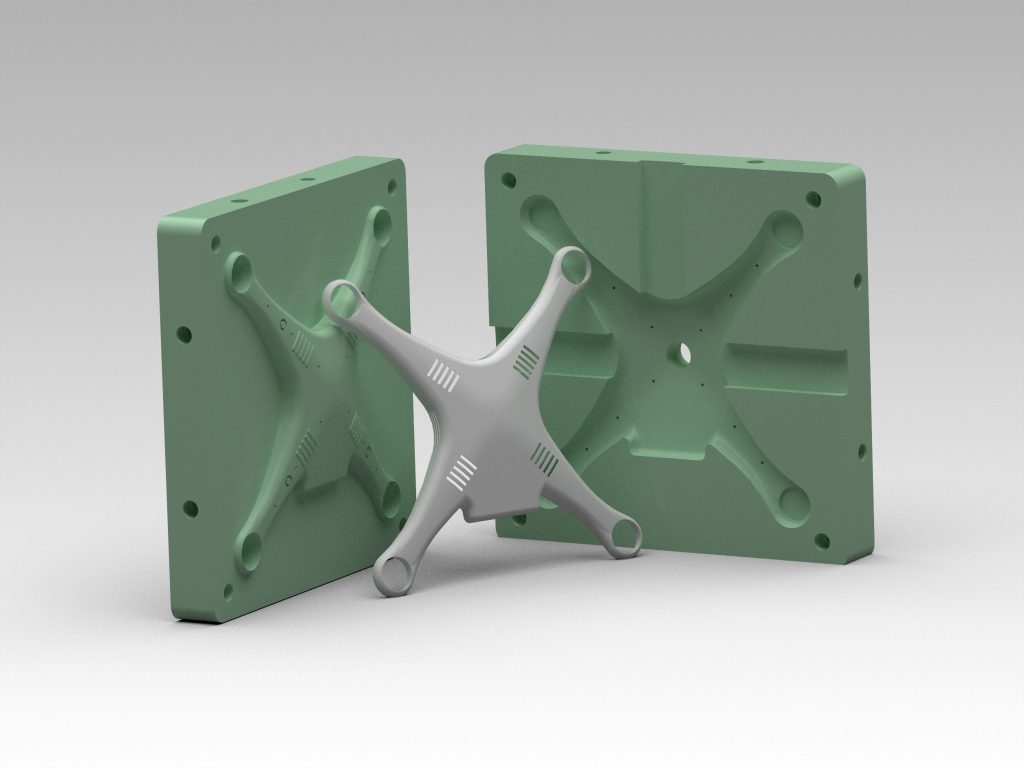

Siemens’ AM software program suite acknowledges the function of the AM inside a course of chain, providing a extra holistic answer, starting with design by way of Siemens NX, one of many prime CAD packages out there. The suite facilitates a seamless AM workflow even for non-NX customers, catering to sectors together with aerospace and automotive. Diegerick talked about, “The distinctiveness of our answer is end-to-end going from design optimization to the ultimate product.” highlighting the significance of a unified atmosphere for design, validation, and manufacturing.

A vital characteristic of Siemens’ suite is its print validation, which permits designers to confirm printability early within the design section, due to the connectivity between design, manufacturing, and simulation instruments. This sturdy integration extends to machine interfacing, with direct entry to main OEMs’ machine software program, making certain a coherent workflow from platform preparation assist technology to course of simulation for steel powder mattress fusion.

Diegerick emphasised the advantages of this interconnected setup, reminiscent of producing compensated fashions for half deformation and updating knowledge all through the method. He added, “While you ramp up from an R&D exercise in the direction of a extra industrialized course of, these instruments allow knowledge administration and are all related to the preliminary software set,” underlining the importance of traceability and course of reproducibility in industrial purposes.

Furthermore, Siemens’ AM software program suite incorporates high quality management instruments, and with related capabilities, it allows customers to simulate their AM actions, together with manufacturing unit setup, earlier than precise implementation. This in depth answer units Siemens aside from level answer suppliers working in silos, thus pushing the frontier in additive manufacturing software program options.

Voting is open for the 2023 3D Printing Business Awards; who’s main the trade?

Siemens’ Tailor-made Method Streamlines Additive Manufacturing for Industrial Shoppers

Diegerick illustrated a typical situation the place giant companies have disparate AM machines scattered throughout numerous world hubs, every using numerous design, manufacturing, and simulation instruments, typically managed by way of rudimentary means like Excel. He recalled a latest interplay with an aerospace consumer who admitted to reaching the boundaries of manageability with such setups, emphasizing the necessity for a extra streamlined method.

He underscored that the majority engagements are with brownfields—established corporations already using AM to some extent as a substitute of greenfields new to AM.

Siemens’ method begins with an understanding of a consumer’s current course of and priorities, whether or not they lean extra in the direction of design or manufacturing. A stepwise implementation of Siemens’ options then follows to stop overwhelming the consumer, Diegerick defined, “We take this method as a result of we have now lots to supply, however we will shortly overwhelm our prospects by throwing all of our options at them.”

Evaluating the scenario to a administration consulting problem, the dialogue highlighted how Siemens navigates by way of technical and managerial dialogues to optimize AM processes for shoppers. A typical engagement includes a proof of idea (POC) on the workflow earmarked for optimization, adopted by a comparative evaluation of key efficiency indicators (KPIs) between current and new workflows. The features are quantified by way of time, knowledge high quality, and traceability, and ultimately translated into monetary metrics.

Diegerick additional talked about the involvement of Siemens’ consulting division, Advanta, in additional complicated, strategic discussions with shoppers. He mentioned, “We have now some very good consultants.” This method demonstrates Siemens’ dedication to not solely offering technical options but in addition making certain that these options align with broader organizational goals, making a compelling case for a extra built-in, consultative method within the AM trade.

Siemens’ Additive Manufacturing Suite Enhances Traceability and Sustainability for Industries

Siemens’ additive manufacturing (AM) software program suite is more and more discovering purposes in traceability and sustainability. One notable instance Diegerick highlighted is the US-based service bureau Sintavia, which predominantly serves the aerospace and protection sectors.

Moreover, Diegerick illustrated a singular case regarding sustainability revolving round using AM for creating robotic grippers at an automotive OEM in Germany. By transitioning from steel to polymer grippers by way of AM, there was a major discount in robotic measurement, contributing to decreasing CO2 emissions. He emphasised, “We have now some very detailed evaluation due to the CO2 calculation instruments that Siemens additionally has.”

The interview additionally delved into the vital matter of traceability, particularly in extremely regulated sectors like aerospace, protection, and medical. Siemens’ AM suite, built-in inside the Teamcenter atmosphere, gives a sturdy knowledge administration answer, enabling complete traceability from the preliminary design section to post-processing. Diegerick elaborated, “Each single parameter that occurs all through the method could be saved on this Teamcenter atmosphere. And that’s essential for our prospects right this moment. It’s undoubtedly a part of the certification course of in aerospace, protection, and medical.”

Navigating Complexities: The Sluggish March of Additive Manufacturing In the direction of Industrialization

I requested Diegerick concerning the slower-than-expected adoption of AM applied sciences, one thing he attributes to the complexity and prolonged certification processes concerned, particularly within the aerospace and protection sectors. Regardless of the preliminary hype round AM being a ‘miracle know-how,’ industrial firms discover it extra intricate and time-consuming than anticipated.

Diegerick notes, “Additive brings a number of benefits, but it surely takes a number of expertise. It is extremely complicated and I feel that’s additionally why the adoption is slowing down, but it surely’s taking longer than anticipated.” The manager mentions that discovering and optimizing the suitable purposes for AM, significantly in aerospace and protection, requires a multi-year certification course of, making firms hesitant to take a position closely on this know-how.

Furthermore, the geopolitical and financial uncertainties exacerbated by the COVID-19 pandemic have additionally slowed adoption. The discussions round Business 4.0 and world provide chains have spotlighted AM, but the monetary and operational hurdles stay important. The pandemic has spotlighted AM’s potential in addressing provide chain points, however client spending slowdowns in sectors like dental have affected the profitability of firms within the AM house.

On a broader scale, the trade’s motion in the direction of Business 4.0 and the digitization of producing processes are slower. Regardless of the promise of Business 4.0, the precise transition is encumbered by numerous elements, together with the complexity of AM applied sciences and the monetary implications of adopting them.

Diegerick additionally discusses the significance of figuring out purposes that make sense for AM and the following want for design optimization and course of stabilization. The journey in the direction of attaining a completely industrialized course of, with factories housing tens or a whole lot of machines, is proving prolonged and sophisticated.

On the journey of additive manufacturing (AM) in the direction of industrialization, the important thing lies in figuring out purposes that make sense for AM, adopted by design optimization and course of stabilization. Nevertheless, the method continues; the following journey towards certification is the place many firms discover a bottleneck.

The panorama is additional difficult by the inflow of recent machines and supplies that, whereas providing new alternatives, additionally add layers of complexity to the AM adoption course of. Diegerick notes the challenges finish customers face in selecting amongst myriad choices, “While you suppose you’ve discovered the suitable factor, then you definately see one thing new.”

Leveraging AI in Streamlining Additive Manufacturing: An Perception from Siemens

The appliance of Synthetic Intelligence (AI) in Additive Manufacturing is gaining traction as industries attempt to beat the intricacies related to the design and manufacturing phases.

Diegerick acknowledges that AM is a extremely iterative course of typically involving a ‘studying by doing’ method. This iterative nature, coupled with the excessive prices related to machine time and supplies, underscores the necessity for AI in optimizing the AM course of. Siemens has built-in AI-supported know-how in sure instruments to expedite design exploration and course of simulation.

One such software, ‘HEEDS,’ aids in design exploration by analyzing a whole lot of designs primarily based on preset parameters to determine the one closest to specified necessities. One other software helps decide the optimum orientation for elements, particularly essential in steel printing, the place parameters reminiscent of down pores and skin and up pores and skin can considerably have an effect on the printability of the half.

Diegerick elaborates, “With AI, yow will discover the optimum orientation. AI can save a fortune.” He additionally mentions the utility of AI in course of simulation, which might analyze a number of supplies primarily based on quite a few parameters affecting the printability of a component.

The dialog additionally veered in the direction of the broader challenges in AM adoption, with Diegerick emphasizing the significance of figuring out appropriate purposes and the necessity for requirements within the trade to information newcomers.

Whereas the trail to full-scale industrialization of AM presents a posh situation, the mixing of AI guarantees a discount within the steep studying curve and useful resource expenditure, making it a pivotal ingredient in advancing the AM panorama.

Reinforcing Provide Chain Resilience by way of Additive Manufacturing: Siemens Foresees a Localized Future

Diegerick highlighted the potential of AM in making certain extra localized and reactive provide procedures, a shift from the centralized manufacturing hubs historically seen in locations like China.

In industries reminiscent of oil and fuel, the emphasis is on minimizing downtime, which could be considerably lowered by having the aptitude to print or restore elements near the place they’re wanted. Siemens Power has leveraged AM to restore or print fuel burners, making certain a swift response when a fuel turbine is down.

The medical sector additionally stands to profit immensely, particularly within the realm of patient-specific implants. Diegerick notes, “Inside, I might say, two or three weeks, they will get a patient-specific implant, and after a few weeks extra, they’re again on their toes.” This not solely underscores the life-altering advantages of AM but in addition its potential to considerably disrupt conventional manufacturing and provide chain paradigms.

Bridging the Additive Manufacturing Hole: A Name for Stronger Transatlantic Initiatives

On a regional observe, the UK, alongside Germany, France, and the Nordics, have been recognized as key areas within the EMEA area driving AM adoption, with aerospace, protection, and medical sectors main the cost within the UK. The geopolitical shifts in recent times have accelerated the tempo of AM adoption within the aerospace and protection sectors.

Diegerick famous that whereas aerospace firms within the UK and France face related hurdles in adopting AM, the essence of competitors thwarts collaborative efforts that would hasten know-how adoption. He remarked, “You would want they might discuss to one another and share experiences in order that it might go sooner. However that’s not potential due to market competitors.”

Diegerick underscored the pressing want for stronger initiatives to foster additive manufacturing (AM) adoption in Europe, echoing considerations concerning the continent lagging behind the US.

A salient level of debate was the success of America Makes, a US initiative bridging authorities, academia, and trade to drive AM ahead. This initiative stands as a testomony to the substantial funding and political will within the US to advance AM. Quite the opposite, Europe’s efforts have to be extra cohesive and daring. Diegerick expressed, “It’s all the time a combination between private and non-private, and it’s very shy initiatives, compared to what America has accomplished, the place the federal government, as much as the U.S. President, has mentioned, additive goes to be a part of strategic initiatives.”

He advocates for a twin method, urging EU-level and local-level actions to bolster AM adoption throughout Europe. The absence of strong governmental backing, each financially and politically, in Europe, versus the US, is considered as a serious stumbling block. Diegerick believes organising hubs with vital sources, akin to the US mannequin, might considerably propel AM adoption amongst European industries.

Diegerick, lamented the slim notion of tech as merely software program in Europe, particularly when juxtaposed with client tech. He highlighted the shortfall of a extra holistic appreciation for AM, encompassing {hardware}, software program, and supplies. He remarked, “Tech is simply software program, however additive is a mixture of issues. It doesn’t get that very same kind of protection or publicity,” when in comparison with extra consumer-facing tech choices.

The dialog navigated in the direction of the essence of collaboration in propelling AM ahead. Diegerick burdened, “What’s essential is collaboration.” He underscored the vitality of open dialogues amongst stakeholders alongside the worth chain regardless of the inherent challenges posed by mental property sensitivities.

Diegerick’s insights function a clarion name for a broader understanding and promotion of AM’s multifaceted nature, urging stakeholders to transcend the software-centric narrative. The discourse additionally accentuates the crucial of fostering collaborative ecosystems to navigate the complicated AM terrain, finally unlocking the know-how’s boundless potential in driving industrial innovation throughout Europe.

What does the way forward for 3D printing for the following ten years maintain?

What engineering challenges will should be tackled within the additive manufacturing sector within the coming decade?

To remain updated with the newest 3D printing information, don’t overlook to subscribe to the 3D Printing Business e-newsletter or comply with us on Twitter, or like our web page on Fb.

Whilst you’re right here, why not subscribe to our Youtube channel? That includes dialogue, debriefs, video shorts, and webinar replays.

Are you searching for a job within the additive manufacturing trade? Go to 3D Printing Jobs for a collection of roles within the trade.

Featured picture reveals a 3D printed prototype mould designed with Siemens NX. Picture through Siemens AG.