Forward of Formnext 2023, 3D Printing Business spoke to the winners of the Formnext Begin-Up problem.

Camila Uzcategui is the CEO and co-founder of Vitro3D. Her enterprise into 3D printing commenced from a want to contribute to international healthcare considerably. By way of her experiences in NGOs and nonprofits, she recognized a obtrusive want for important medical gadgets in well being clinics, sowing the seeds for her exploration into additive manufacturing.

Uzcategui’s educational endeavor led her to a PhD in Materials Science and Engineering, concentrating on 3D printing purposes, which she completed in 2021. Her dissertation was centered on the characterization of supplies for 3D printing aimed toward tissue engineering and regeneration, understanding resins to foretell the standard of 3D printing constructions precisely.

Uzcategui remarked, “If we’re good at characterizing resins, then we might be even higher at matching the mechanical properties of those explicit sorts of tissues.”

However somewhat than work with extra established 3D printing expertise, Uzcategui’s firm has gone in the direction of volumetric 3D printing, or as they like to name it, Volumetric Additive Manufacturing.

Vote now within the 2023 3D Printing Business Awards.

Pioneering Volumetric Additive Manufacturing: Vitro3D’s Strategic Shift In direction of Business-Related Options

Volumetric additive manufacturing is a nascent but promising side of superior manufacturing expertise. Whereas the normal layer-by-layer 3D printing was the main target of Uzcategui’s Ph.D., the exploration into volumetric additive manufacturing got here post-PhD throughout her post-doctoral work, spurred by its potential to surmount challenges like assist constructions and dealing with extremely viscous resins.

Uzcategui underscored the benefit of volumetric expertise over standard 3D printing strategies, stating, “It was superior to see what challenges that present layer-by-layer 3D printing couldn’t overcome, whereas volumetric was like, ‘Oh, we’re not nervous about that,’ like assist constructions, for instance, or extremely viscous resins.” This transition initially unfolded as extra of a “ardour challenge,” shifting from customary 3D printing to a expertise that effectively addresses these hurdles.

Relating to the strategic imaginative and prescient, Vitro3D was eager to keep away from the everyday deep tech startups’ dilemma of being “options on the lookout for an issue.” Uzcategui expressed a proactive stance in figuring out industries past healthcare that would profit promptly from this expertise, acknowledging that realizing the “large dream” of tissue engineering could be a long-term endeavor, probably spanning 5 to 10 years.

Vitro3D is now eyeing sectors like electronics and dentistry, the place volumetric expertise might considerably impression within the close to time period. This pragmatic method goals at making certain the corporate isn’t “elevating cash for five years with out income” however partaking in significant, revenue-generating ventures that edge nearer to their final aim of revolutionizing tissue engineering and regeneration.

The Intricacies of Volumetric Additive Manufacturing: A Deep Dive with Vitro3D’s CEO

Uzcategui described how volumetric 3D printing manipulates mild from varied angles to create a 3D object from a digital mannequin. Uzcategui highlighted, “The algorithm is an important half as a result of that’s how we take a 3D digital object and decompose it in these totally different angles, after which reproject it, to create a 3D object within the resin. That’s all based mostly on a fancy algorithm, which generates the projected pictures.” It’s essential to account for materials properties and the resin’s response to mild, making certain the resin receives the exact quantity of sunshine for polymerization. The software program is the important thing that unlocks this functionality.

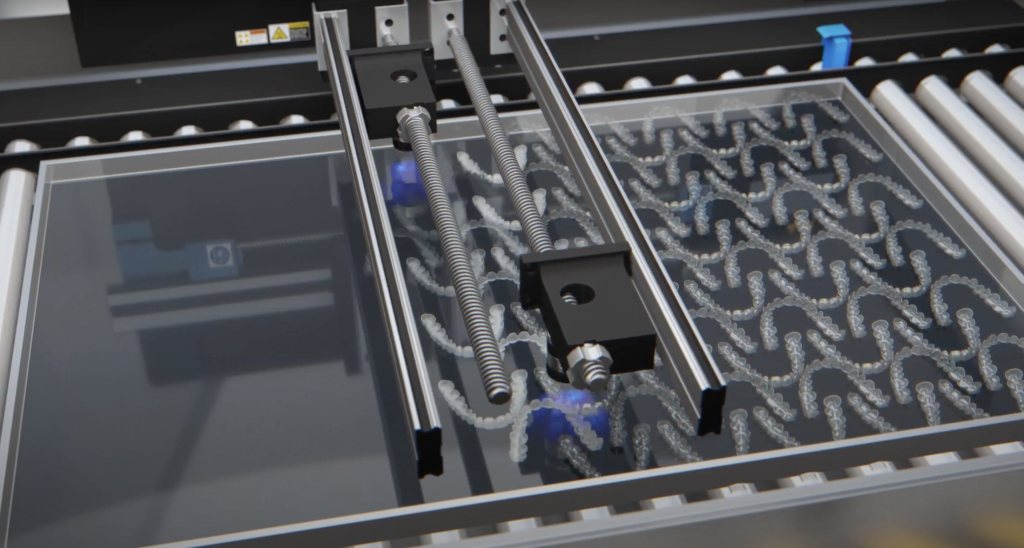

Exploring the mechanism additional, Uzcategui talked about that Vitro3D invented a brand new excessive dimensionality volumetric additive manufacturing (HD VAM) methodology the place a translating two-dimensional cone of sunshine is utilized, thereby inputting 4 dimensions of knowledge into the fabric versus the standard three. She famous, “We name it excessive dimensionality VAM as a result of somewhat than simply inputting three dimensions of knowledge by way of rotation and a two-dimensional picture, we’re placing 4 dimensions of knowledge by way of translation in X and Y and a two-dimensional cone of sunshine containing data.”

The sunshine supply, sometimes a laser, is essential for sustaining high-quality mild with an extended focus, which is crucial for projecting by way of the complete quantity. Uzcategui acknowledged, “We would like our depth of focus to be as large as doable, beginning with 3 cm.”

Addressing the dimensions limitation inherent in volumetric 3D printing because of the depth dimension, Uzcategui detailed how the HD VAM methodology decouples dimensions, permitting for extra intensive dimensions in X and Y whereas retaining a small dimension in depth. Vitro3D’s method has an eye fixed on broader industrial purposes.

Scaling Volumetric Additive Manufacturing: Vitro3D’s Exploration into Bigger Dimensions and Materials Versatility

The corporate is making ongoing efforts to discern the utmost printing measurement doable with its expertise. The present most stands at a diameter of eight centimeters, although Uzcategui hints at a tantalizing imaginative and prescient, “Might we now have a cartridge the dimensions of a desk somewhat than having a field? Might we now have some form of gantry system that may be put in in a producing plant?”

This revolutionary method goals to combine the HD-VAM course of seamlessly into current manufacturing strains, doubtlessly ushering in a brand new period of on-site, large-scale additive manufacturing. Central to this endeavor is their proprietary algorithm, described by Uzcategui because the “magic” behind their expertise. This algorithm replicates the printing course of earlier than it commences, making certain the resin polymerizes solely the place desired. Uzcategui defined, “The algorithm takes in details about the fabric, the optics, and the mechanics and simulates the printing course of.”

The dialog highlighted a big benefit of volumetric 3D printing—its aptitude for dealing with extremely viscous resins, a problem for standard layer-by-layer methods. In customary methods, resin circulate for layer replenishment is a time-consuming bottleneck, notably for extremely viscous resins. Nonetheless, Vitro3D’s expertise bypasses this hurdle. Uzcategui elaborated, “As a result of no resin flows throughout the printing course of, it’s only a static quantity. We don’t care if the fabric is a stable. Relating to our viscosity limitations on the upper finish, we haven’t discovered any to date as a result of we’re not restricted by materials circulate..”

Vitro3D’s pursuits replicate a compelling trajectory in the direction of surmounting current obstacles in 3D printing expertise, heralding a paradigm shift in how additive manufacturing integrates inside conventional manufacturing environments.

Vitro3D Tackles Novel Materials Challenges in 3D Printing

Sure resins essential for digital elements and connectors current a viscosity problem for conventional 3D printers. Uzcategui remarked on a specific case the place a agency needed to innovate round this problem, “They’d some success with their printer as a result of they warmth these viscous resins.” This instance underscores the workaround necessitated by the constraints of current layer-by-layer printing strategies when coping with such supplies.

Moreover, Uzcategui highlighted the emergence of nano gels discovering purposes within the dental sector, which additionally presents a viscosity problem. The viscosity will increase with the nano gel loading, necessitating revolutionary processing strategies to deal with them effectively.

Vitro3D’s HD-VAM expertise emerges as a promising answer, aptly suited to course of these revolutionary but difficult supplies with out the necessity for added heating or modified chambers, as required by some layer-by-layer printers.

The benefit manifests not solely within the printing course of itself, the place volumetric printing materializes the article concurrently, however extends to post-processing phases, usually a bottleneck within the general manufacturing timeline.

Uzcategui defined, “We have now an enormous benefit in pace as a result of the half materializes without delay, and also you’re not going layer by layer, so a whole lot of the time, you’re slicing your speeds per half very considerably.” This pace enhancement is pivotal because it straight impacts the manufacturing lead time, a essential issue for industries aiming to cut back time-to-market.

Moreover, she delved into the essential facet of post-processing, highlighting that the absence of assist constructions in volumetric 3D printing considerably reduces the time spent on post-printing cleanup. She talked about, “You’re printing with out assist constructions or with very restricted assist constructions another way that, layer by layer, 3D printing simply can’t entry.”

Uzcategui additionally touched on an important level about making certain high quality and repeatability throughout elements, stating, “An enormous focus of our firm is to automate post-processing to get extra dependable elements, not solely within the printing however within the materials properties themselves.”

Vitro3D’s method in the direction of not simply accelerating the printing course of but in addition streamlining post-processing displays a holistic understanding of commercial manufacturing wants.

Value Effectivity in Volumetric Additive Manufacturing: Vitro3D’s Software program-Centric Strategy

Vitro3D is gearing as much as provide a cost-efficient method to 3D printing, the place the emphasis just isn’t on costly {hardware} however on clever software program. Uzcategui defined that, not like some 3D printing setups that would price as much as one million {dollars}, their system makes use of pretty customary {hardware} elements just like these utilized in conventional layer-by-layer 3D printers. The excellence lies of their proprietary algorithm, which drives the volumetric 3D printing course of.

This software-centric method, she suggests, not solely retains the {hardware} prices manageable but in addition permits for the event of customized {hardware} options tailor-made to the wants of their prospects. Uzcategui provides, “We consider in an open resin system that permits prospects to make use of their very own supplies in our HD-VAM system, the place the fabric solely must be licensed by Vitro3D and added to the algorithm’s materials library.”

The primary worth proposition, as per Uzcategui, revolves round “offering software-based options” aimed toward accelerating improvement in a way that {hardware} alone can’t obtain. She added, “Our mixture is extra of a low-cost {hardware},solution-based software program method, somewhat than making an attempt to promote a bit of apparatus for lots of of hundreds of {dollars} with service charges..”

The Challenges and Promise of Volumetric 3D Printing

The nascent stage of volumetric 3D printing has inherent limitations, particularly in measurement and backbone, that immediate skepticism. But, Uzcategui is optimistic. She believes that regardless of these limitations, their HD-VAM volumetric 3D printing course of holds a promise of fixing important challenges in sure industries, challenges which are past the attain of present 3D printers.

Uzcategui highlighted the rising restrictions on the usage of ‘eternally chemical compounds’ like PFAS and PFOA in Europe, restrictions she anticipates will quickly be a worldwide norm. She acknowledged, “We are able to use extremely viscous resins that may usually have higher materials properties in the case of toughness,” making volumetric 3D printing a probable candidate for creating alternate options to those chemical compounds.

One of many pivotal benefits of volumetric 3D printing, elucidated by Uzcategui, is the potential to disrupt conventional manufacturing steps. She illustrated this by referencing the creation of a easy digital connector, explaining that at present, it requires a number of steps to encase steel with plastic. Nonetheless, with volumetric 3D printing, one might “have a bunch of steel items within a cartridge, after which we will create an element round that steel,” eliminating a number of manufacturing steps, decreasing waste, and doubtlessly dashing up the iteration of latest expertise designs.

The dialogue ventured into overprinting and overmolding, the place volumetric 3D printing shines with its functionality for creating high-value, high-mix, low-volume elements. Uzcategui sees this as a pathway to rapidly iterate on new applied sciences with out the hefty monetary burden of tooling

The intricacies of making certain exact materials conduct amidst a maelstrom of transferring resin that’s consistently altering and shrinking demand a profound understanding and meticulous management of the light-material interplay. She highlights that the method is “depending on understanding and crossing that gelation threshold,” indicating a razor-thin margin for error.

Noting the success of firms like Carbon, who’ve invested closely in understanding how supplies work together with mild, Uzcategui underscores the elevated significance of this interplay in volumetric additive manufacturing. “In our case, we now have a multidimensional course of the place the light-material interplay is much more vital than layer-by-layer 3D printing,” she related to customary manufacturing strategies like injection molding.

With eyes set on commercialization, Vitro3D is on observe to deploy its first off-site system subsequent yr and is in discussions with early adopters for pilot tasks slated for late 2024. The startup’s journey towards commercialization is anchored in a collaborative ethos, aiming to work alongside business gamers to craft options that tackle particular manufacturing hurdles.

As a fledgling startup, Vitro3D can be on a quest for business expertise and collaborative partnerships, a mission Uzcategui hopes to advance on the upcoming Formnext expo, one in every of Europe’s premier 3D printing occasions. There, she goals not solely to showcase Vitro3D’s expertise but in addition to forge connections in industries the place their expertise might resolve persistent manufacturing challenges.

Uzcategui sees the burgeoning curiosity and entry of different gamers within the volumetric 3D printing area as a testomony to the expertise’s rising legitimacy. She posited, “It’s superior to see that there are different volumetric 3D printing firms on the market and that we’re all fixing challenges in very other ways. Not solely does everyone have their very own method of doing it, however we every have distinctive advantages.”

With a conviction that their tailor-made method units them aside in a aggressive market, Vitro3D is inching nearer to its aim of being a disruptive pressure in industrial expertise, assembly prospects precisely the place their challenges lie.

Be certain to go to Vitro3D throughout Formnext 2023; discover them in Corridor 11.1 at sales space B55C.

What does the way forward for 3D printing for the subsequent ten years maintain?

What engineering challenges will have to be tackled within the additive manufacturing sector within the coming decade?

To remain updated with the most recent 3D printing information, don’t neglect to subscribe to the 3D Printing Business e-newsletter or observe us on Twitter, or like our web page on Fb.

When you’re right here, why not subscribe to our Youtube channel? That includes dialogue, debriefs, video shorts, and webinar replays.

Are you on the lookout for a job within the additive manufacturing business? Go to 3D Printing Jobs for a collection of roles within the business.

Featured picture exhibits a prototype HD-VAM system on the Vitro3D lab in Boulder. Picture by way of Vitro3D.