Minnesota-based 3D printer producer Evolve Additive Options has introduced the commercialization of STEP Components Now, a brand new elements manufacturing service designed to scale additive manufacturing to fulfill calls for in serial manufacturing. The corporate additionally launched two new supplies into its portfolio: Nylon PA-11(A) and Grey ABS.

Evolve’s new choices have been unveiled at Formnext 2023 throughout a press convention headed by Evolve President and COO Jeff Clean, Jeff Hansen, SVP of Go-to-Market, and Melissa Hanson, VP Advertising and marketing.

Observe the full protection of Formnext 2023.

STEP Components Now additional enhances Evolve’s half ordering service by means of the corporate’s strategic companions and STEP manufacturing facilities.

Evolve not too long ago introduced a strategic partnership with German 3D printing service supplier alphacam GmbH, who now provide Thermoplastic Electrophotographic (STEP)-manufactured elements as a service to prospects in Europe. On-demand manufacturing service supplier Fathom Digital Manufacturing additionally runs a STEP manufacturing middle, offering Evolve’s 3D printing serial manufacturing capabilities to prospects within the US.

“We’re not promoting a prototyping system, so we’re distinctive within the targets that we’re going after. And that’s actually within the injection molding house,” defined Jeff Hanson. “Fathom’s prospects are beginning to migrate and leverage this know-how as a bridge to manufacturing, in some circumstances for finish use elements.”

Jeff Hanson added that this new providing allows a shift from prototyping to manufacturing. “Our prospects would are available for prototypes after which they’d go away. However with Step Components Now we will develop their utility, undergo their prototype iterations, and simply maintain hitting the print button to go to manufacturing.”

“It’s lastly delivering on the guarantees that additive has made to the business for the final 30 years.”

Scaling manufacturing with STEP Components Now

Launched again in 2017, STEP 3D printing know-how allows excessive pace 3D printing of engineering-grade thermoplastics 50 instances quicker than SLS 3D printing, enabling a shorter time to market with “toolless” manufacturing.

The electrophotography-based additive manufacturing (EPSD) course of employs electrophotographic imaging and deposition. Right here, materials is deposited layer by layer through a shifting belt, till the specified half has been 3D printed.

Based on Evolve, STEP is the one additive manufacturing know-how available on the market able to delivering the constancy, floor end, accuracy, and materials properties wanted to reliably and repeatedly 3D print end-use elements at scale.

Prospects can now quote and order STEP 3D printed elements immediately from Evolve by means of the STEP Components Now e-commerce portal. This portal reportedly permits for better utility growth, increasing serial-3D printing manufacturing for extra use circumstances.

“The core of Step Components Now could be accessibility and utility growth,” commented Jeff Hanson. “The core of this mannequin is speaking to the shoppers, seeing their geometries, speaking to them about their manufacturing course of and their constraints with these processes, after which working with them by means of design for additive manufacturing, turning these into manufacturing functions.”

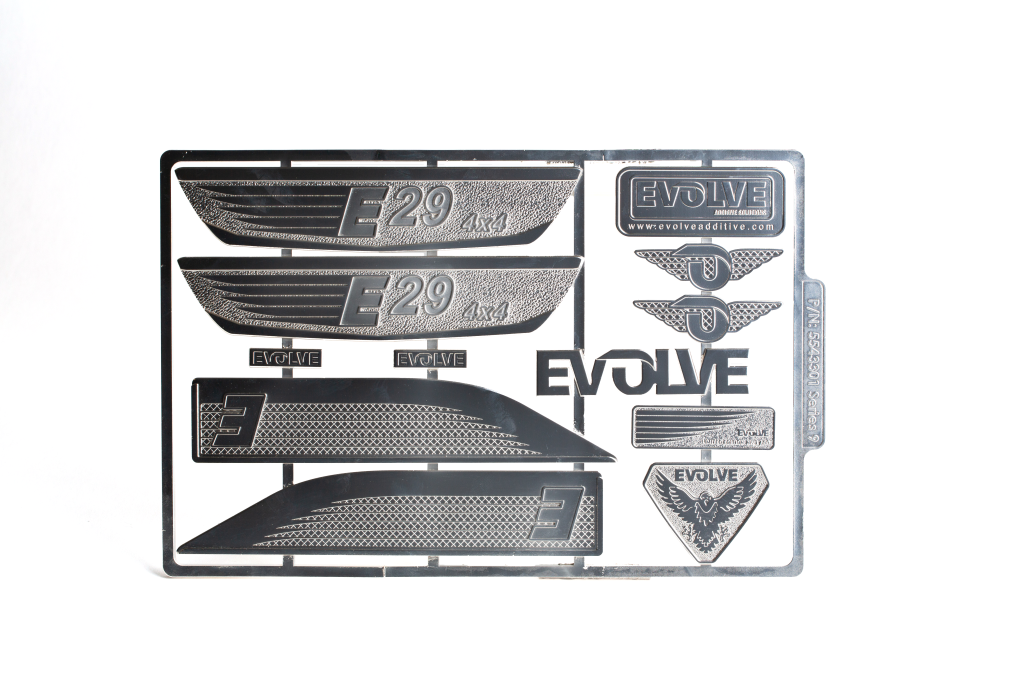

Evolve’s STEP providing has already attracted curiosity for giant scale, serial manufacturing runs. Jeff Hanson outlined one unnamed automotive firm as quoting the manufacturing of 40 distinctive badges. The corporate is claimed to be seeking to produce 100,000 of every distinctive badge, taking the full quantity to 4 million printed elements. Jeff Clean additionally pointed to {the electrical} wearables, client items, and medical industries as requiring giant manufacturing runs.

The fee and time financial savings of STEP are stated to be substantial. For example, 736 automotive fender brackets can reportedly be 3D printed in 6.5 hours. Moreover, Evolve has 3D printed 40 LED display screen parts for visible show producer Daktronics at $83 per piece, in comparison with $10,000 apiece utilizing injection molding.

Evolve’s rising materials portfolio

Evolve’s new PA-11(A) has been optimized for STEP, and reportedly provides vital mechanical efficiency benefits over powder mattress fusion PA-11. For example, this new materials provides superior elongation at break, greater influence energy, and a better warmth deflection temperature (HDT). As such, PA-11(A) STEP 3D printed elements are suited to a variety of demanding manufacturing functions.

A brand new Grey ABS materials has additionally been launched, complementing Evolve’s current Black ABS. This new materials is claimed to exhibit mechanical properties inside 10% of bulk injection molded ABS, while possessing structural shade distinction for positive textures.

Evolve additionally informed 3D Printing Business that it’s creating new multi-material capabilities, permitting for elements to be 3D printed possessing a number of colours and materials properties in a single construct. This providing isn’t but commercially accessible, however Evolve has already demonstrated the aptitude in various pattern 3D prints.

Subscribe to the 3D Printing Business publication to maintain updated with the most recent 3D printing information. You can too observe us on Twitter, like our Fb web page, and subscribe to the 3D Printing Business Youtube channel to entry extra unique content material.

Are you curious about working within the additive manufacturing business? Go to 3D Printing Jobs to view a choice of accessible roles and kickstart your profession.

Featured picture exhibits Evolve Additive Options STEP manufactring flooring. Picture through Evolve Additive Options.