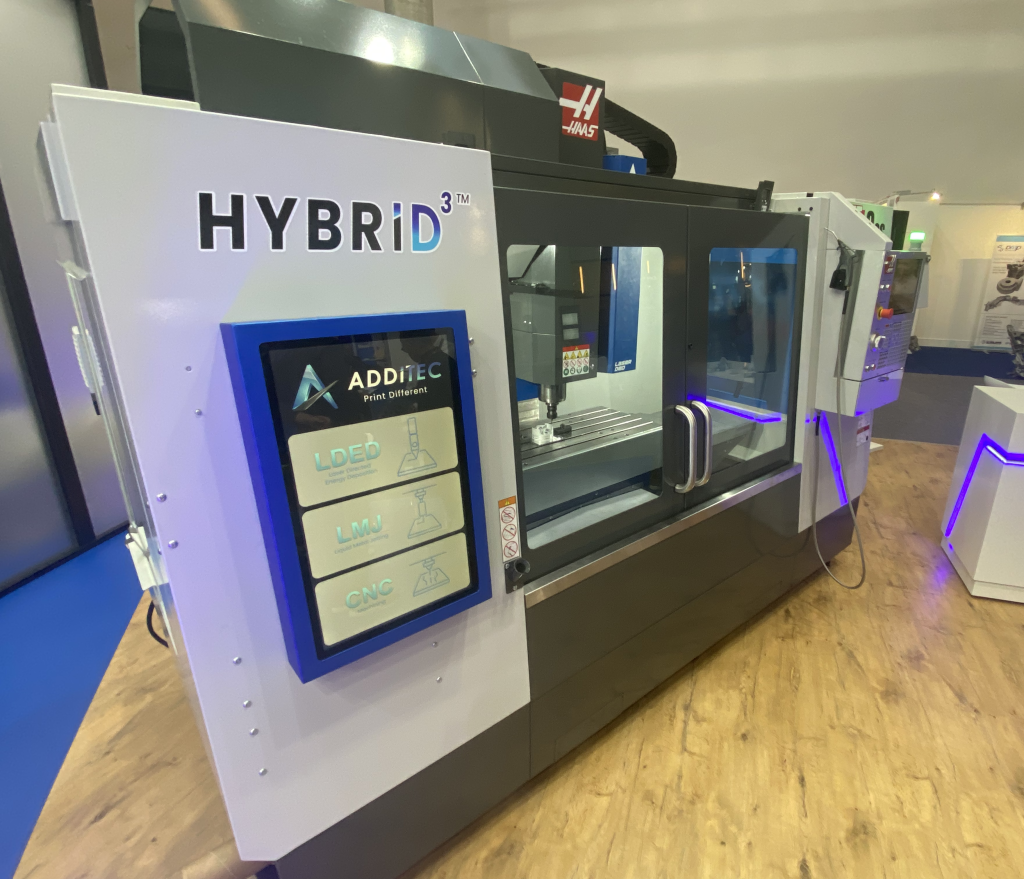

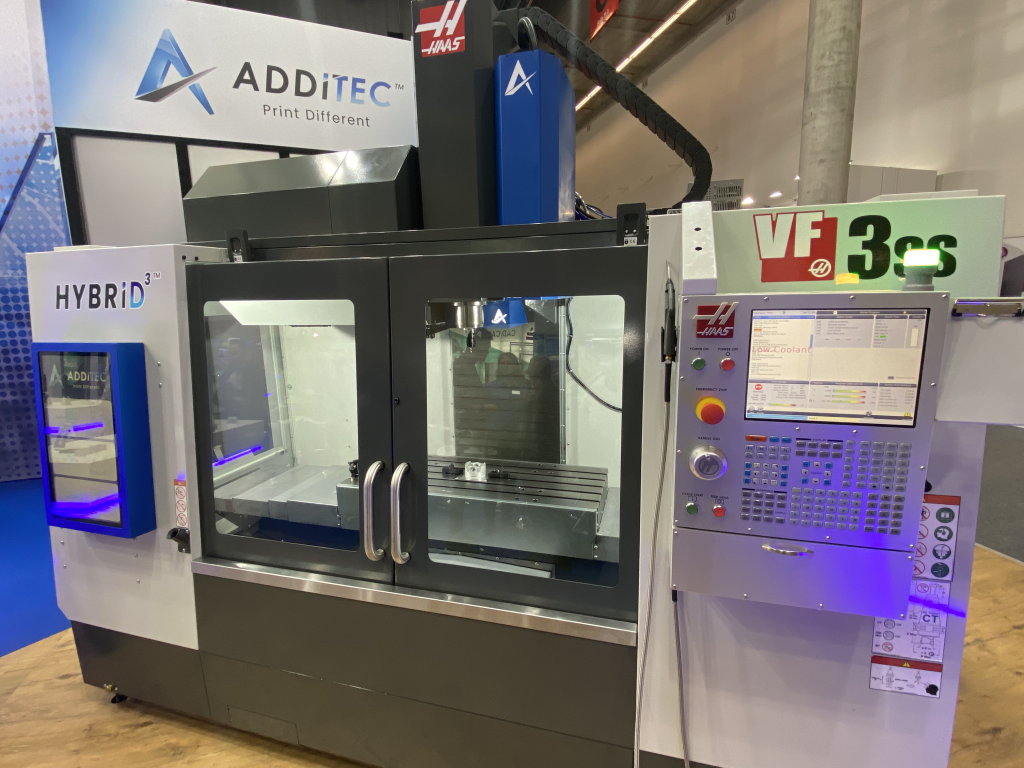

US-based metallic 3D printer producer Additec has introduced its latest metallic 3D printer, the Hybrid 3, at Formnext 2023. The Hybrid 3 combines liquid metallic jetting (LMJ), laser directed vitality deposition (LDED), and CNC capabilities into one platform.

Primarily focused in the direction of the manufacturing of metallic elements for automotive purposes, Additec’s new 3D printer combines 0.5 mm LMJ decision with a excessive 4 kg/hr LDED deposition fee. The Hybrid 3’s two additive processing heads additionally allow multi-material metallic 3D printing. This new 3D printer is at present appropriate with iron, nickel, aluminum, and copper alloy supplies.

Additec reportedly developed this new three-technology system within the house of 11 weeks. Additec inherited the LMJ expertise from Xerox, following the acquisition of the corporate’s additive manufacturing enterprise unit, Elem Additive Options, earlier this yr.

3D Printing Trade spoke with Additec Founder and CEO Brian Mathews in the course of the Frankfurt-based trade-show to be taught extra about this new providing.

Comply with the full protection of Formnext 2023.

Additec’s new three-in-one metallic 3D printer

Each LMJ and LDED processes use low-cost COTS welding wire to 3D print near-net form elements with 100% materials utilization. LMJ is notable for its high-resolution 3D printing capabilities, whereas LDED affords excessive deposition charges.

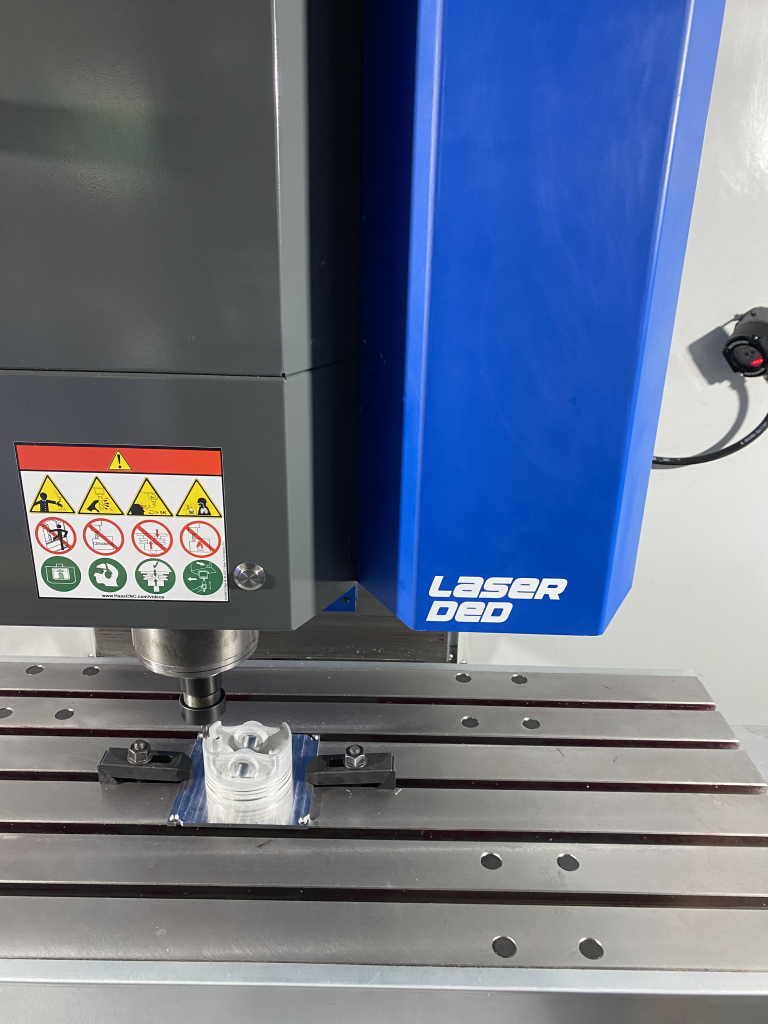

The Hybrid 3’s LDED system employs a 6kW fiber laser with a 1080 nm wavelength, and might produce a layer thickness between 0.8 and 1.2 mm. The LMJ toolhead can obtain a minimal layer thickness of 0.24 mm, and affords a notable 0.5 mm decision. “We now have two unbelievable applied sciences,” defined Mathews. “They’re each extremely sustainable, with all the fabric ending up within the remaining half.”

The extra CNC machining system affords a 40” x 20” x 25” construct quantity, possessing a most spindle velocity of 12000 rpm and a 21.1 m/min chopping velocity.

Though at present restricted to iron, nickel, aluminum, and copper, Mathews highlighted that the Hybrid 3 might be scaled to make the most of extra supplies sooner or later.

“We’re quickly increasing the fabric vary,” defined Mathews. “We’ve integrated a laser help, and that is the primary time this has been executed with the liquid metallic course of. We’re utilizing the laser for native heating, and that may give us a dramatically improved materials vary.”

In keeping with Mathews, the corporate has already examined copper and silver with its new system. “I absolutely count on liquid metallic to have the same materials vary to laser DED sooner or later,” Mathews added.

The benefit at which the Hybrid 3’s printhead will be changed was additionally highlighted as being key. Certainly, with LMJ, Mathews said that many of the expertise is positioned inside the printhead. As such, if the client experiences a technical difficulty, “the probabilities are very excessive that the difficulty goes to be within the printhead as a result of that’s the place all of the expertise is.”

“It’s very nice as a result of we will really simply exchange the client’s printhead, we don’t even want to go to,” defined Mathews. “We are able to simply ship the refurbished printhead the subsequent day, and the client can simply exchange the printhead,” as there isn’t any difficult set up course of. That is mentioned to considerably cut back downtime and reduce prices.

In the end, Mathews claimed that the Hybrid 3 has been developed with the longer term in thoughts. “We predict liquid metallic goes to be a dominant participant within the trade due to its traits, decision particularly,” commented Mathews. “We don’t wish to wait to have a product like this for a number of years the place liquid metallic does all of it. We predict the complementary applied sciences collectively permit us to have a unbelievable product sooner.”

Technical specs and pricing

Additec hopes to start out delivery its new 3D printer to prospects by the top of Q1 subsequent yr.

Mathews highlighted that the Hybrid 3’s pricing will begin at round $500,000. Nevertheless, the corporate’s white label product is predicted to start out delivery by Q2 subsequent yr, and might be priced within the $200,000 vary.

| Parameter | Laser DED | LMJ |

| Most Laser Energy | 6 kW | – |

| Laser Kind | Fiber Laser | – |

| Laser Wavelength | 1080 nm | – |

| Layer Thickness | 0.8 – 1.2 mm | 0.24 mm (min.) |

| Most Deposition Fee | 4 kg/hr | 0.5 kg/hr |

| Wire Feed Inventory | 0.8 – 1.2 mm Φ | 1.6 mm Φ |

| Decision | 2.5 mm | 0.5 mm |

| Course of Management Closed Up | Sure | Sure |

Subscribe to the 3D Printing Trade e-newsletter to maintain updated with the most recent 3D printing information. You can too comply with us on Twitter, like our Fb web page, and subscribe to the 3D Printing Trade Youtube channel to entry extra unique content material.

Are you curious about working within the additive manufacturing trade? Go to 3D Printing Jobs to view a number of out there roles and kickstart your profession.